Born right into a farming household, Jagat Kalyan spent his childhood taking part in within the lush inexperienced fields of Hajipur, Bihar. He noticed his household toil day and evening to domesticate banana timber, however as quickly as they harvested the fruit, the tree was axed down.

“It takes about 9 months to develop bananas, and as soon as the fruits are harvested, farmers want to cut down the tree because it produces fruits solely as soon as in its life cycle. I’d see piles of banana timber dumped as waste in a nook of the sphere. Clearing the sphere additionally turns into a headache for farmers,” he says.

Information reveals that India leads the world in banana manufacturing with an annual output of about 14.2 million tonnes. After harvesting, virtually 60 % of banana biomass is left as waste!

Jagat didn’t have an answer to this subject till 2021 when he recognised this inefficiency within the agricultural course of and determined to show waste into wealth.

By his zero-waste startup, Taruwar Agro, he utilises banana tree waste by changing it into banana fibre, which finally serves as a uncooked materials for numerous merchandise — similar to handicrafts, yarns, sanitary pads, and banana leather-based. By turning this waste into wealth, he has established a multi-lakh enterprise.

From school pals to co-founders

After finishing his engineering and MBA, Jagat secured a job at a startup that targeted on local weather change and the atmosphere. After working for almost a 12 months, he acquired numerous job provides from corporations in Tanzania and Dubai. As a substitute of accepting these alternatives, Jagat aspired to run his personal sustainable firm in his native state of Bihar.

“The job was very demanding and we had been required to work for 10 to 12 hours. I’d typically focus on with my school pals Satyam Kumar and Nitish Verma about quitting jobs to construct one thing significant of our personal,” he says.

Quickly after, Jagat and his school pals began researching numerous points that wanted their consideration. “By our work, we wished to place Bihar on the world map. That’s when it hit us that since Hajipur is thought for its banana manufacturing, why don’t we deal with banana waste — a problem that each one of us grew up seeing on our fields,” he provides.

To form their desires into actuality, the trio give up their jobs and launched Taruwar Agro in 2021.

Their modern method focuses on changing banana waste into beneficial merchandise, contributing to environmental sustainability and creating financial alternatives for native communities.

The startup sources banana waste from at the very least 30 native farmers. “Relying on the scale of the tree, we pay Rs 5 and Rs 25 per tree. Now, they don’t seem to be simply incomes by promoting fruit but additionally tree waste. Generally, many farmers don’t settle for cash, as this course of advantages them in clearing fields. This protects them labour prices of Rs 1,000,” says Jagat.

Leaving no waste behind

After extracting fibre from banana tree waste, the startup makes a variety of merchandise from banana fibre folders, yoga mats, baskets, work, cushion covers, coasters, and extra. Whereas doing so, it maintains a zero-waste method in all its processes.

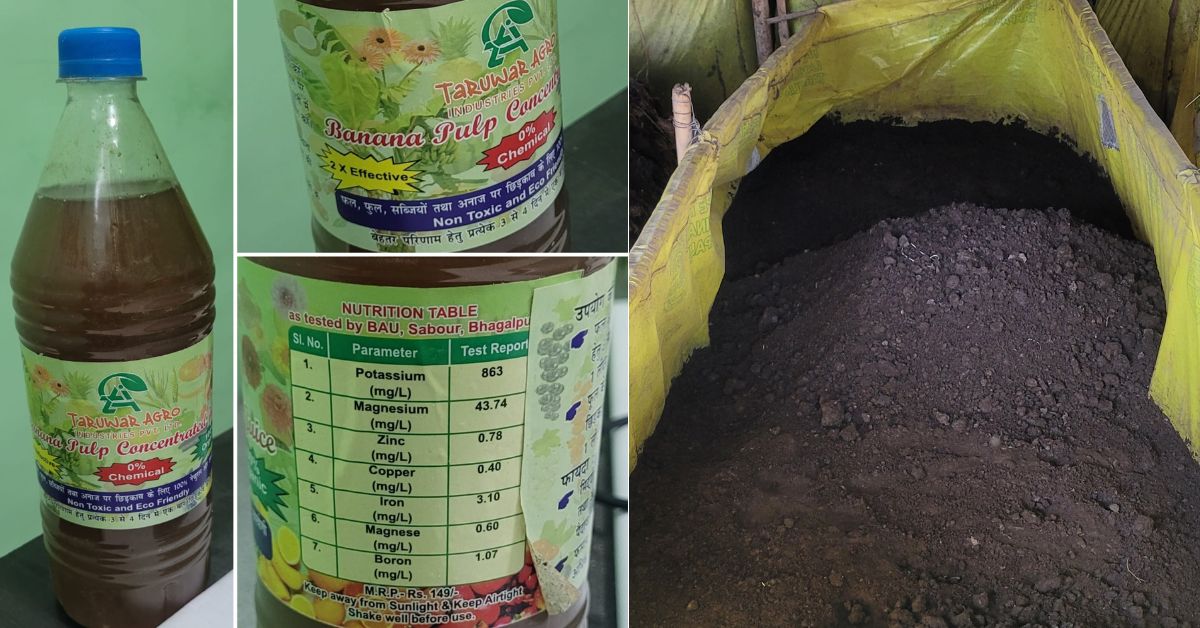

It utilises the leftover pulp from the fibre extraction and processes it into high-quality vermicompost. Moreover, Taruwar extracts banana liquid from the pulp, which serves as a pure fertiliser wealthy in micronutrients like potassium and iron. “So the whole lot within the course of is changed into one thing beneficial,” he factors out.

The startup’s dedication to sustainability and social impression has garnered important traction, with an annual turnover of Rs 50 lakh within the earlier monetary 12 months. Each month, the startup utilises as much as 600 kg of banana fibres from waste. By offline and on-line advertising and marketing, it has established its buyer base in Kerala, Gujarat, Delhi, Uttar Pradesh, West Bengal, Punjab, Tamil Nadu, and Madhya Pradesh.

Satyam, who takes care of advertising and marketing and gross sales of the corporate, says, “We’ve got been in a position to develop a great market base in India and now we aspire to enter into exports. By the tip of this 12 months, we are going to begin exporting to different nations. A variety of corporations are engaged on agriculture residues to make merchandise, however our zero-waste method helps us stand out available in the market.”

Jagat, Satyam, and Nitish usually are not solely entrepreneurs but additionally champions of sustainable innovation, paving the way in which for a greener future and a extra inclusive economic system. Their initiative showcases the potential to create constructive change by reimagining waste as a beneficial useful resource and contributing to the round economic system.

By their dedication and imaginative and prescient, Taruwar demonstrates that small actions can result in important impacts, inspiring others to embrace sustainability and group empowerment of their entrepreneurial endeavours.

Trying again at his swap from the company world to a purpose-driven journey, Jagat says, “My household was hesitant once I determined to give up my job. After you make investments your time and efforts in pursuing increased schooling in engineering and an MBA, anybody can count on you to accept a high-paying job. However after the preliminary doubts, they understood the place my true calling was and prolonged their assist.”

“At present, I’m glad that banana waste in a radius of 10 kilometres from our manufacturing unit is getting used as uncooked supplies for helpful merchandise. With this, farmers are additionally getting further financial advantages. Banana waste is not a headache for them now,” he smiles.

Edited by Arunava Banerjee; All pictures: Jagat Kalyan.