Study extra about egg weighing, hygiene, grading and high quality

Editor’s word: This text is an excerpt from the Cobb Breeder Administration Information and extra articles will comply with. The Information was designed to spotlight vital elements which might be most certainly to affect flock efficiency. The administration suggestions mentioned have been developed particularly for Cobb merchandise. The suggestions are supposed as a reference and complement to your individual flock administration abilities as a way to apply your data and judgement to acquire constantly good outcomes with the Cobb household of merchandise. To learn or obtain the entire Information or to view Cobb’s different administration guides, click on right here.

Egg Weighing

There are appreciable benefits in weighing a pattern of eggs every day to set up the development in egg weight. The evaluation of this development is a helpful information for flock efficiency and can give an early indication of issues. Egg dimension is partly decided by the body weight of the females at picture stimulation, the event between 21 and 25 weeks of age, and the extent to which females turn out to be over weight after peak manufacturing. Delays of picture stimulation will outcome in bigger eggs initially and all through the lifetime of the flock. Eggs over 70 g are inclined to have a poor hatch and may significantly have an effect on the typical hatchability of the flock. That is probably the rationale for a extra speedy decline in hatch after 50 weeks of age. The egg weights proven within the Cobb dietary supplements (accessible at Cobbgenetics.com) ought to be anticipated from regular mum or dad flocks when our suggestions for body weight, feed ranges and feed specs are adopted. Within the egg assortment room, bulk weigh not less than 90 eggs instantly after the second egg assortment, which normally happens round mid-morning. Ensure that to exclude double yolks, misshapen, very small and cracked eggs. Each day egg weights, when plotted on a graph, will give a sign of potential issues that ought to be investigated instantly.

Computerized egg weighing

Many egg packing machines weigh all of the eggs. Common calibration of the size is critical to forestall hatching eggs loss. Within the first 8 weeks, the utmost weight must be adjusted twice weekly to forestall bigger eggs being mistaken for double yolks. A 1 g distinction in most weight can have a big affect. At all times set the minimal weight requested by the hatchery.

Managing egg weight

Egg weights are necessary to take care of within the latter a part of the manufacturing interval as weights affect eggshell high quality, hatchability and chick high quality. Investigations and area experiences report that eggs over 70 g are inclined to hatch much less and have extra late embryonic mortality when not sufficient cooling is out there within the hatchers. Attempt to keep a mean egg weight under 70 g for so long as potential!

Usually, egg weights will enhance throughout manufacturing however ought to be managed to will increase of 1 gram each 2.5 to three weeks after 35 weeks of age. Ideally, common egg weight ought to be shut to 70 g between 55 and 60 weeks of age.

The next suggestions can be utilized to manage egg weights:

- Management feminine bodyweights into peak manufacturing and after peak manufacturing. This includes adjusting and optimizing peak feed quantities and decreasing the feed after peak accurately.

- Change from breeder-1 (B-1) to breeder-2 (B-2) feed when the egg weights attain 60 g in Cobb FF and 62 g in Cobb SF. Cobb recommends solely B-1 and a B-2 feed be used as a result of, with the correct discount in feed quantities, the hen weight and egg weights ought to be managed.

- Begin manufacturing on time. It would take a hen longer to succeed in a 60 g common egg weight when manufacturing begins at 24 weeks in comparison with 25 weeks. A decrease egg weight at 30 weeks signifies, basically, that the egg weight will likely be decrease at 40 and infrequently 50 weeks of age.

Egg Hygiene

Below sure circumstances, it might be useful to sanitize hatching eggs. Peracetic acid can be utilized instead. Fumigation or disinfection of hatching eggs on the farm ought to be utilized as quickly as potential to forestall bacterial penetration earlier than the cuticle matures. Eggs ought to be handled with chemical-based antimicrobials — scraping, rubbing, or washing the eggshell will injury the cuticle and take away the bodily and antimicrobial barrier. Don’t moist hatching eggs with liquid sanitizers. Solely beneath low humidity circumstances will this process be an appropriate instrument to cut back contamination. Because the eggshell permeability will increase after 24 hours and makes the eggs extra inclined to bacterial invasion, the eggs ought to be sanitized as quickly as potential. Thus, if fumigation or disinfection on the farm just isn’t potential, eggs ought to be sanitized on the hatchery as quickly as they’re obtained.

Vital administration practices:

- Rejected eggs ought to be saved nicely away from hatching eggs.

- It’s important to position hatching eggs rigorously into the transport tray with the small (pointed) finish dealing with down.

- The egg dealing with room should be stored clear and neat.

- Nest pads in mechanical nests ought to be stored clear particularly with older flocks.

- Preserve good vermin management within the egg retailer.

- The egg dealing with room is the primary stage of egg cooling and it’s advantageous to maintain it cooler than the laying home, however hotter than the egg storage room.

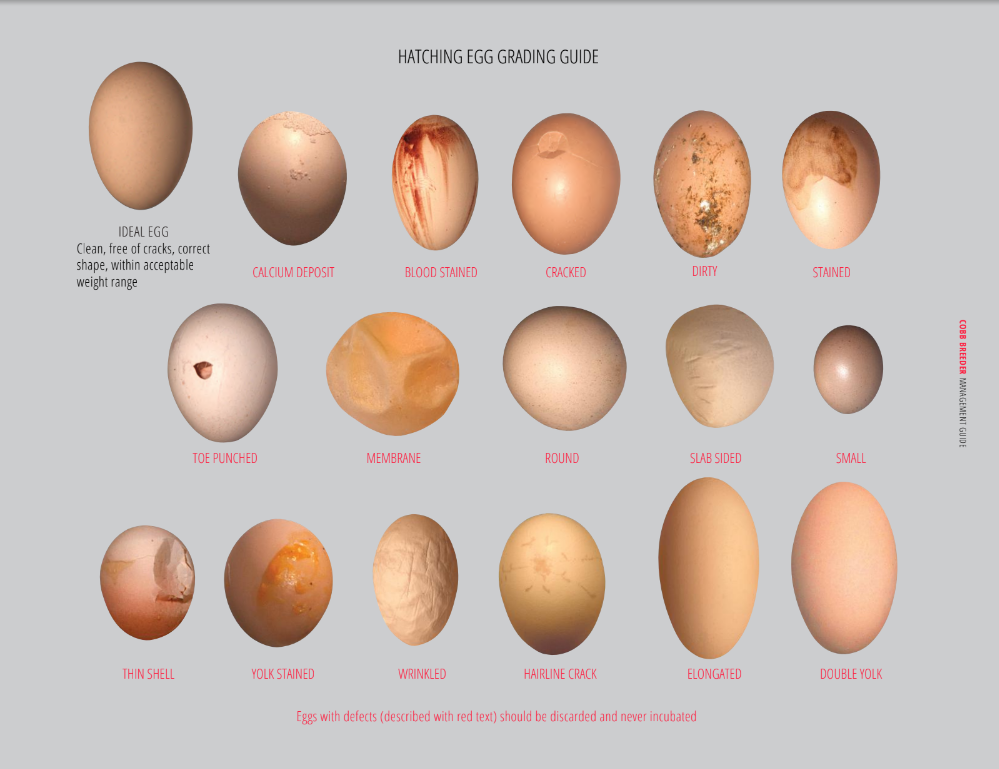

Egg Grading

Egg grading ought to be achieved with care to forestall mechanical injury to hatching eggs. Take away and discard eggs which might be unsuitable for hatching together with:

- Soiled or stained as outlined by firm coverage

- Cracked

- Small – relying on hatchery coverage

- Very massive or double yolk

- Poor shell high quality

- Grossly misshapen

Eggshell High quality

Nearly 50% of discarded eggs are because of shell high quality points. A pale brown or white shade could be the primary indication of poor eggshell high quality for broiler breeders. In pale eggs, it’s probably that cuticle deposition and calcium accumulation are lowering or not full which could possibly be a results of diet and illness. In some circumstances, eggshell high quality points are because of untimely oviposition. Shell thickness and energy are vital elements and ought to be monitored over the lifetime of a flock. There are a selection of assessments that may consider shell high quality together with breaking energy, shell weight and thickness. Shell weight and thickness could be readily measured on website. A pattern of 30 eggs per flock is really helpful. Use comparatively clear flooring eggs as an alternative of nest eggs since flooring eggs are more likely to be discarded.