Longer conditioning occasions: useful for animal well being, difficult for enzymes

For many years, pelleting has been a typical apply in animal feed manufacturing. Particularly in broiler vitamin, it’s well-known for growing power effectivity and, consequently, enhancing efficiency (McKinney et al., 2004).

Longer conditioning occasions: useful for animal well being, difficult for enzymes

Within the early days of pelleting, the trade employed rising temperatures and conditioning occasions starting from 15 to 30 seconds. Nevertheless, in up to date practices, prolonged conditioning occasions have gotten more and more prevalent, providing a number of benefits:

- Enhanced pellet high quality attributable to elevated warmth and moisture absorption

- Manufacturing of extra sturdy and uniformly formed pellets because of the formation of bonds between particles

- Improved gelatinization of starch

- Discount in mud and wastage

- Enhanced feed palatability, and

- Mitigation of microbial progress.

Rising the conditioning occasions proves to be a helpful device in successfully lowering microbes, particularly in combating salmonella and different pathogens. This enchancment is essential for enhancing the cleanliness of feed. It isn’t unusual to see conditioning occasions of as much as 6 minutes for breeder feed, 4 minutes for salmonella-free feeds in broilers, and three minutes for swine diets.

Whereas these adjustments profit animals’ total well being and well-being, they pose a problem to enzyme software. Enzymes, being proteins, are susceptible to excessive temperatures, resulting in denaturation and lack of performance. The moist circumstances additional contribute to adjustments within the cost and form of enzymes. Conditioning involving publicity to excessive temperature and moisture exacerbates this problem, leading to vital denaturation and everlasting lack of enzyme exercise.

How can we protect enzyme exercise successfully?

There are a number of methods enzyme suppliers cope with such a problem in pursuit of preserving enzyme exercise in pelleted feed.

1. Coating of enzymes

Over the past 15-20 years, quite a few enzyme suppliers have used coating know-how to guard their enzymes. Sadly, this profit is compensated by sure disadvantages:

Uneven coating results in much less uniformity and decrease effectiveness

Coating processes could not all the time end in a constant masking of enzymes, probably resulting in variations in enzyme exercise and efficacy. An uneven distribution throughout the feed can result in animals failing to satisfy efficiency expectations.

Stability and storage could also be impacted

Coated enzymes could have diminished stability throughout storage, particularly if the coating isn’t successfully designed to guard the enzyme from degradation over prolonged durations. Storage circumstances and shelf life should be rigorously managed to keep up enzyme efficacy.

Impact within the animal could also be impaired

Relying on the kind of coating materials used and the coating high quality, the effectiveness of the enzyme can differ. Too robust safety of the enzyme can result in diminished availability within the GIT due to inadequate launch or, within the case of insufficient coating, extreme launch earlier than reaching the goal website for digestion. Each inaccurate coatings negatively affect digestibility and animal efficiency.

Coating can negatively affect the atmosphere

Some coating supplies could have environmental implications, particularly if they don’t seem to be biodegradable or launch dangerous substances into the atmosphere throughout degradation.

Whereas coating could supply some safety towards excessive temperatures, its efficacy underneath extra prolonged conditioning occasions stays unsure, as most checks are performed with shorter durations of 15-45 seconds versus 120-180 seconds and even longer, which is turning into the brand new norm.

2. Liquid software post-pelleting

Some enzyme suppliers began providing liquid enzymes for post-pelleting liquid software to cope with the decrease inherent thermostability of their enzymes. This was not splendid, however a means round resolving the challenges of excessive temperature and longer conditioning time throughout the pelleting course of. Nevertheless, in-depth discussions with feed mill operators and nutritionists reveal that this method poses some critical hidden challenges:

Shorter shelf life

Liquid enzyme formulations normally have a shorter shelf life. That is notably difficult if the enzymes should be shipped lengthy distances.

Feed mills want extra tools

Liquid enzymes are utilized by a post-pelleting liquid applicator system (PPLA). This brings extra engineering with extra upkeep and pit stops, affecting the general throughput of the feed mill and growing the prices.

In some instances, adjusting the pelleting machines to the output of the PPLA’s spray nozzles to make sure a homogenous and even software of enzyme on the pellets could cut back the general pellet manufacturing charge, particularly in large feed mills with very excessive throughput.

Uniform distribution of the enzyme is difficult

The homogeneous and uniform spraying of the enzyme answer on the pelleted feed requires meticulous consideration. For instance, blockage of spray nozzles with mud particles hindering spray and going unnoticed isn’t unusual. As enzymes are utilized with a sure nutrient matrix worth in feed, the insufficient distribution of the enzyme can affect animal efficiency.

3. There’s a higher means: Intrinsically thermostable enzyme

The biotechnological advances in enzyme improvement, particularly in enzyme discovery and engineering, allow us to develop intrinsically thermostable enzymes that maintain increased temperatures and longer conditioning occasions.

One such xylanase, Axxess XY from EW Diet, was an consequence of this devoted innovation method to unravel this concern of excessive temperature and longer conditioning time. Axxess XY is intrinsically thermostable and, due to this fact, wants no coating. Axxess XY originates from a bacterium referred to as Thermotoga Maritima. This bacterium is remoted from sizzling water springs close to volcanic grounds. This provides Axxess XY an evolutionary benefit to maintain excessive temperatures but additionally very moist circumstances.

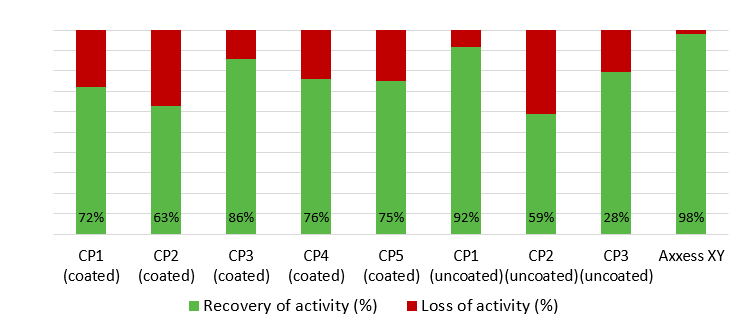

Axxess XY outperforms opponents underneath dry warmth circumstances

In rigorous testing underneath excessive dry warmth circumstances at 90°C for 60 minutes, Axxess XY exhibited outstanding efficiency, surpassing all examined coated and uncoated xylanases from international suppliers (see Determine 1).

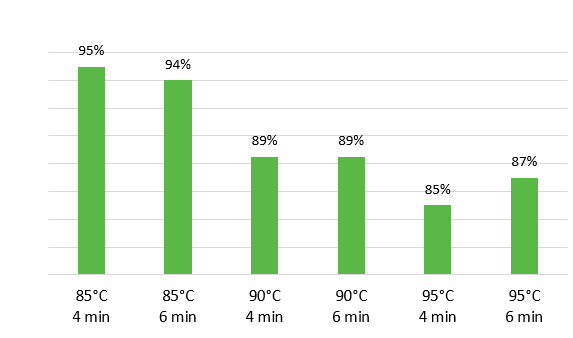

Axxess XY withstands conditioning at excessive temperatures and very long time

Moreover, to evaluate the steadiness of Axxess XY underneath sensible circumstances with excessive temperature and longer conditioning occasions, Axxess XY was included right into a industrial broiler weight loss program (corn, wheat, soya blended weight loss program) and subjected to temperatures of 85°C, 90°C, and 95°C for 4 and 6 minutes. The research revealed over 85% restoration even at 95°C and 4 to six minutes of conditioning time (see Determine 2).

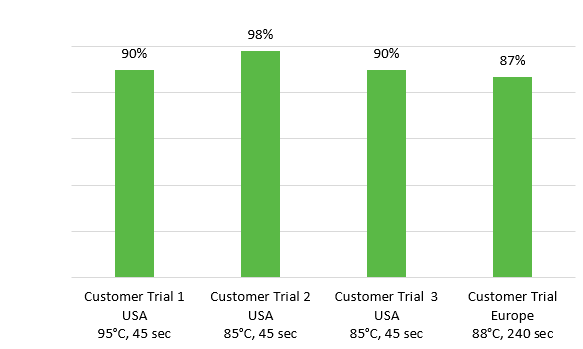

Axxess XY thrives within the rigorous pelleting environments of economic feed mills

In sensible software checks throughout numerous industrial feed mills with numerous conditioning processes, Axxess XY persistently demonstrated excessive restoration charges, confirming its suitability for real-world circumstances (see Determine 3).

Conclusion: Assembly future challenges in feed processing

With the escalating pelleting temperatures and prolonged conditioning occasions geared toward enhancing feed hygiene, enzymes face elevated challenges. Axxess XY, with its excellent efficiency underneath demanding circumstances, exemplifies the sort of innovation wanted in enzyme know-how. It not solely gives confidence to animal feed producers with ease of use in numerous processing circumstances but additionally assures nutritionists that the enzyme successfully reaches animal intestines, selling higher digestion and total efficiency. As feed processing evolves, such improvements grow to be essential to satisfy future calls for.

Axess XY launches formally on March 13 at VICTAM, in Bangkok.