CalPid D+ YOUR answer to boost animal welfare maximising manufacturing

One of many best challenges in fashionable poultry farming is guaranteeing the welfare of fast-growing broilers, which regularly face critical lameness points. Amongst these, Bacterial Chondronecrosis with Osteomyelitis (BCO) emerges as a big concern, being essentially the most prevalent explanation for lameness in business broilers. This infectious illness poses a significant problem to the poultry business, affecting each animal welfare and operational profitability.

Calpid D+ is a key product, extremely water soluble, designed to enhance animal welfare and farm KPIs, straight translating into higher efficiency margins. Calpid D+ presents enhanced skeletal integrity and, consequently, fewer scratches, cellulitis, and carcass harm throughout processing.

How can CalPid D+ assist?

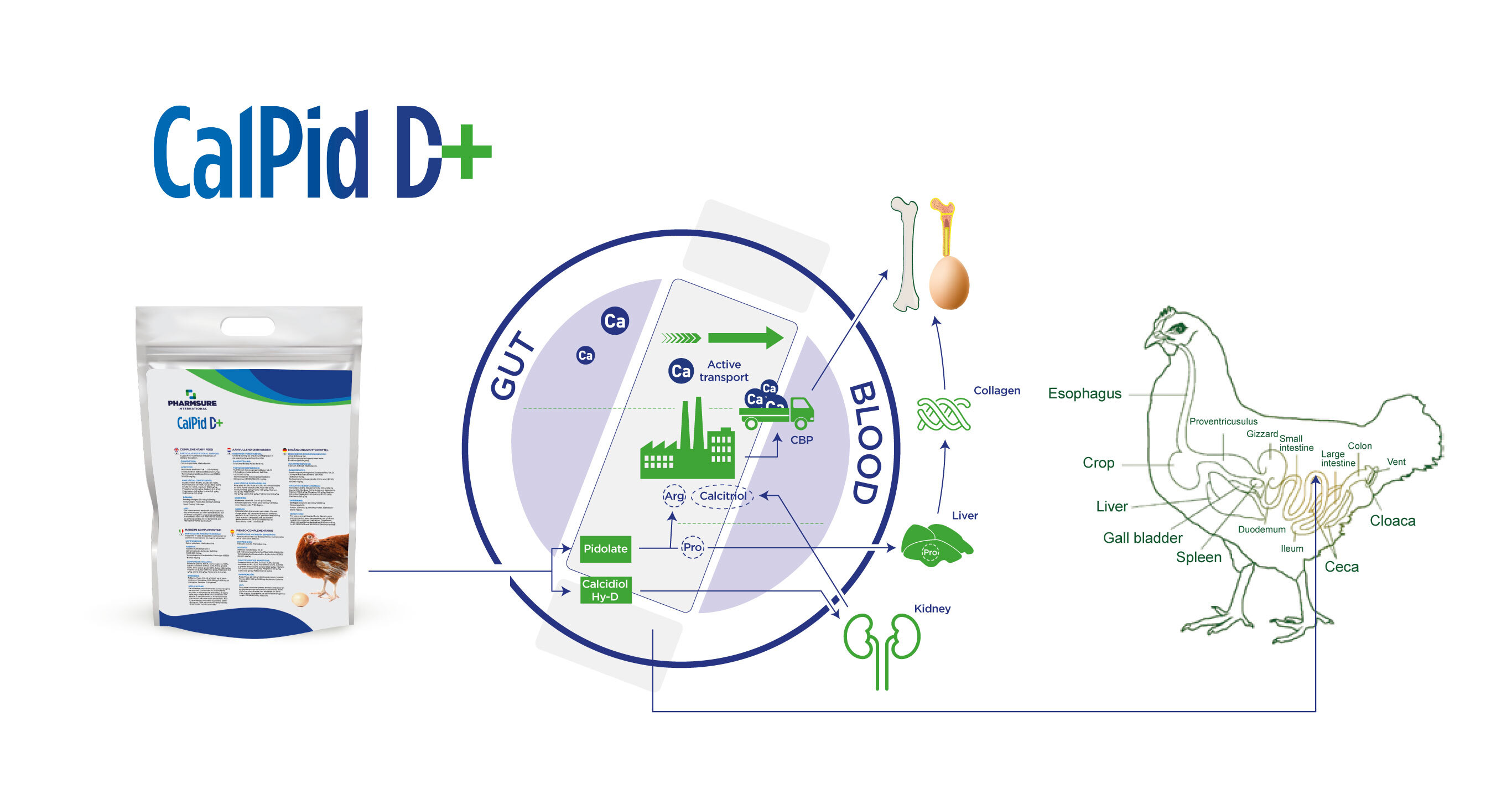

Not like different merchandise in the marketplace, CalPid D+ promotes environment friendly calcium absorption due to the synergistic motion of its two energetic components: Vitamin HyD® and calcium pidolate.

- On one hand, Vitamin HyD®, the energetic type of Vitamin D with larger absorption and effectiveness, will increase the expression and synthesis of calcium channels and Ca transport proteins throughout the enterocytes, enhancing calcium absorption even in animals challenged by stress, age, and/or malabsorption points.

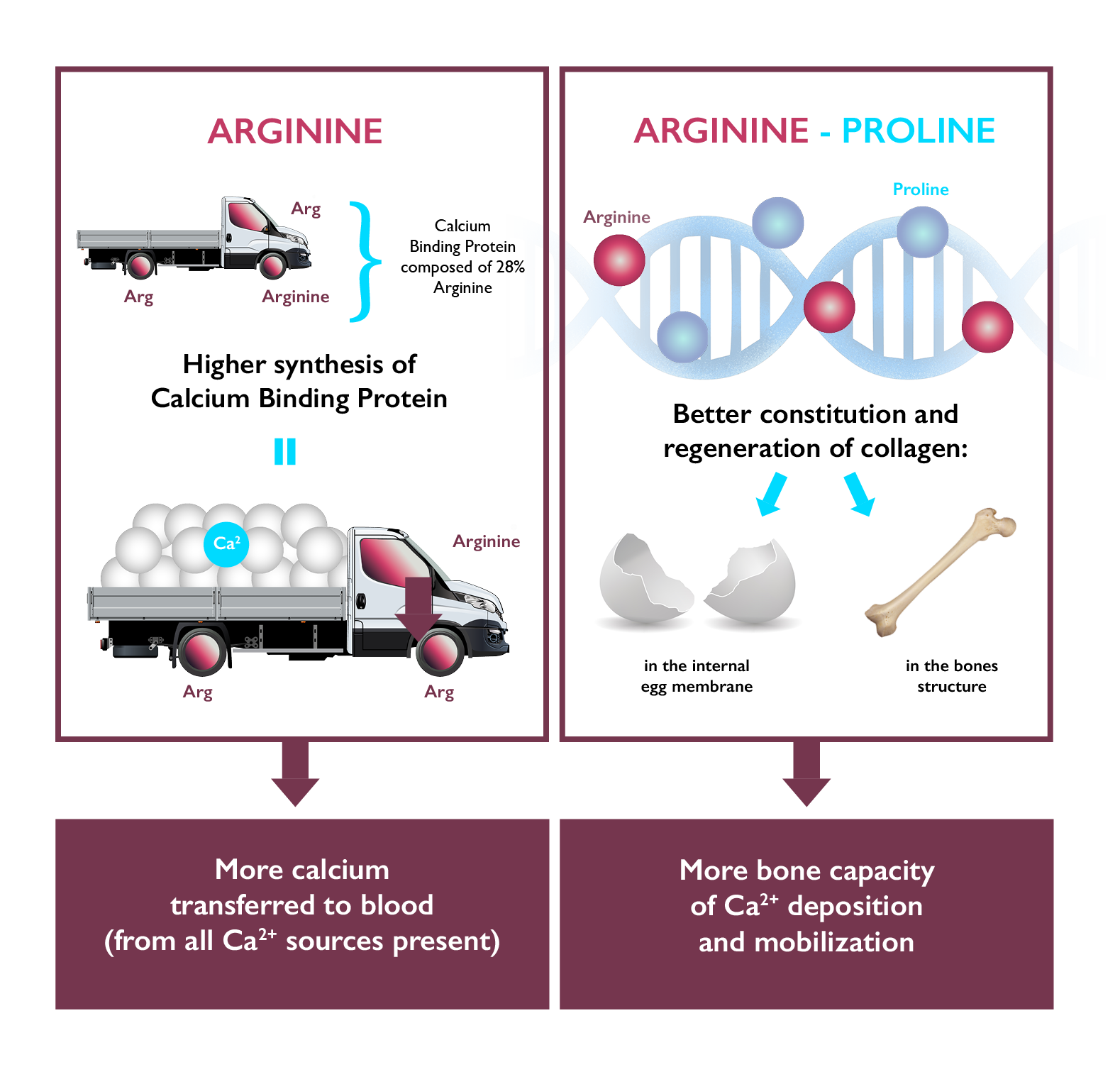

- Calcium pidolate, however, with its two molecules of pidolic acid, that are precursors of arginine and proline, key elements of bones and eggshells, offers the important parts that enterocytes have to construct calcium transport proteins, Calbindin.

It’s NOT a calcium supply.

This synergistic answer enhances the energetic transport of calcium in enterocytes, contributing to the formation of bones with higher bone density, ready for the present challenges of mechanical stress that finally lead to bacterial invasion, joint degeneration, septicaemias, and cellulitis, impacting manufacturing and financial return. It optimises the absorption of dietary calcium with no need to change the formulation or have an effect on the Ca/P ratio!

A research in the UK over 10 manufacturing cycles

On this context, we current the outcomes of a two-year research carried out by the distinguished English poultry veterinary service, Slate Corridor Veterinary Observe, and its Scientific Director, Dr. Adrian Knoetze., on a farm with 190,000 broilers, protecting 10 manufacturing cycles, 5 earlier than and 5 after beginning to use CalPid D+. The farm had a historical past of excessive ranges of bacterial lameness, processing rejections, and water hygiene issues, significantly because of the presence of sewage fungus (Sphaerotilus natans) within the ingesting system.

The utilization protocol was primarily based on veterinary expertise and information of calcium metabolism by the accountable veterinarian, Dr. Knoetze.

In chicks, there are two important phases of calcium want, so a two-intervention protocol was established:

- The primary intervention, from day 0 to five, goals to assist the deficiency of Vitamin D and accessible calcium throughout the first days, which is because of the lower in Vitamin D ranges absorbed from the yolk sac, mixed with the low stage of feed consumption noticed in chicks throughout their first week of life.

- The second intervention, ranging from the second week, is aimed toward supporting the hen as its skeletal progress fee will increase, particularly after the dietary transition. The analysis of tibial dyschondroplasia confirmed improved mineralisation and progress plate integrity at 21 days of age, supporting early use of the product.

The farm had earlier expertise utilizing further Vitamin D dietary supplements; nevertheless, well being and manufacturing outcomes had been comparatively higher when utilizing CalPid D+.

The research revealed vital enhancements in well being and efficiency indicators in chickens, in contrast over a mean of 5 manufacturing cycles:

- Leg Well being: 63% fewer discards as a consequence of lameness.

- Antibiotic Use: 51% discount.

- Processing Rejections attributed to the farm: 29% discount.

- Tibial Dyschondroplasia: Incidence decreased by 50%.

- Financial Acquire: 13% improve in monetary return per sq. metreper week.

Higher skeletal integrity interprets into fewer birds creating osteomyelitis and septicaemia. Because of this, higher gait scores within the homes, fewer birds scratching and creating cellulitis. The discount in septicaemia is believed to be a direct impact of decrease osteomyelitis, because it usually progresses to septicaemia throughout the manufacturing cycle. This works by lowering microfractures and tears in bone vasculature when birds topic their legs to rotational stress.

In conclusion, higher mineralisation and skeletal system integrity resulted in higher progress charges and fewer bacterial lesions noticed at slaughter, leading to considerably decrease processing rejections. Improved leg well being additionally resulted in decreased antimicrobial use whereas offering higher efficiency margins.

These advantages underline the significance of adopting progressive options that enhance animal well being and welfare and provide vital financial returns for producers. This research reaffirms CalPid D+’s dedication to providing a sophisticated and efficient answer for one of the vital important issues in fashionable poultry farming, offering a stronger skeleton and higher financial returns for producers.

Continued use of Calpid D+ interprets into higher animal welfare by lowering lameness whereas considerably rising financial return

Well being parameters:

- Important discount in mortality fee and tibial dyschondroplasia.

- The share of lameness discards considerably decreases.

Feed effectivity:

- Improves feed conversion ratio (FCR).

- Improves European Poultry Effectivity Issue (EPEF).

Productive parameters:

- The age at slaughter can lower with the usage of CalPid D+, as a consequence of optimum slaughter weight being reached earlier.

- Using antibiotics considerably decreases in circumstances of bacterial lameness.

- Lower within the share of rejections throughout processing.

- Enhance in manufacturing and financial return per sq. metre per week.