Nearly all of us, the poultry individuals, know what biosecurity is about. For the traders, it means spending numerous cash to stop disasters, and for the workers, it means many difficulties to stop troubles! Taking showers, altering garments and boots, cleansing and disinfecting, controlling rodents and bugs, limiting entrances to the farm and so many different duties are examples of measures now we have to take to lower the chance of illness occurrences in farms or to stop the illness from spreading to the opposite farms.

Dr. Makan Hooshangi (DVM)

Veterinarian, Turkey Administration Specialist

There are numerous educational and linguistic definitions for “biosecurity” and there are additionally many helpful approaches discovered on the net, however how concerning the preliminaries equivalent to the entire plan design or the supplies utilized in buildings and gear? How vital are such concerns in influencing the entire process of biosecurity in a poultry farm? The very fact is that oftentimes easy issues which we don’t pay sufficient consideration to have large results!

Biosecurity is an costly apply that begins with the very first steps of creating a farm or a hatchery

These embody the premises’ location concerns together with the space to different farms or high-risk areas, native local weather, and the vegetation of the world. As these are the preliminary necessities of respecting biosecurity laws, any mistake or miscalculation in these respects might be irreversible! Furthermore, the design and the supplies of the entire web site and the buildings are the following essential components for the biosecurity course of. Underestimating the significance of those components might be an costly mistake and can’t be simply corrected after ending the constructions, or is not going to be cost-effective to be corrected. Due to this fact, it’s indispensable that the above concerns be taken significantly previous to the development section. The separation of high-risk and low-risk areas within the farm, as the primary and second biosecurity zones, the right design of high-risk entry routes (feed vehicles, and so forth.), the homes’ exhaust followers course, the sewage system, the ground slopes, the isolation sort, the floor drainage design, the placement and course of every constructing and services, and so forth. are points that have to be considered when designing and setting up poultry websites. As well as, the positioning needs to be designed in a manner that so far as attainable, no CCTV or controlling individual be wanted for biosecurity watch. Utilizing one-way paths, dividing partitions, mounted home windows or different related concerns that may scale back the biosecurity breaches to zero might be simply utilized within the designing section.

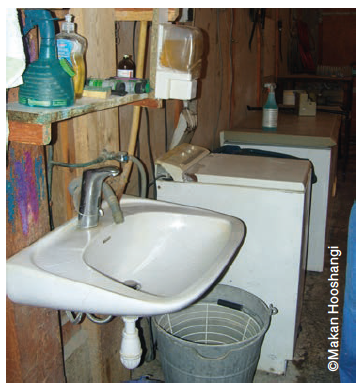

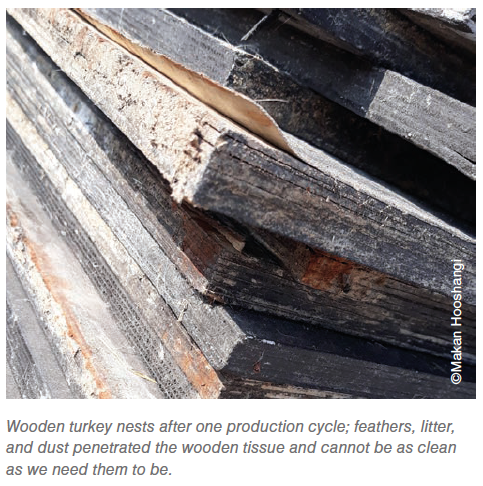

Aside from finding, designing, and setting up a farm, probably the most vital concerns in biosecurity is the supplies utilized in buildings or within the gear. On a poultry web site, particularly in farms and hatcheries, all of the surfaces have to be washable with the least perforations, seams, joints, or folds. Utilizing wooden, PU foam, material or glass wool in buildings or gear are errors which can’t be corrected simply. None of those supplies might be washed or disinfected correctly they usually would be the causes of steady illness occurrences in farms, one cycle after the opposite. Normally, correcting such buildings or changing such gear may be very costly. Alternatively, persevering with the job regardless of such deficiencies just isn’t cost-effective both. It’s an costly dilemma!

The very fact is that no sensible disinfection might be efficient on such surfaces or notches. The microorganisms in natural residues inside wooden, PU foam or glass wool, and so forth. are nearly unreachable! That could be a large challenge in lots of farms, particularly the outdated ones. So many efforts and assets are wasted as a result of it was not thought of earlier than beginning the development or earlier than shopping for the gear.

As many companies, poultry farming is a specialised enterprise, typically very difficult, and it wants totally different professionals to work collectively to satisfy the wants and adjust to the requirements, particularly biosecurity and hygiene requirements. It’s essential for all these professionals to work as a group and take a look at the job with their totally different views. Nevertheless, they have to be conversant in the crucial factors of the job. Errors flip into disasters simply and quickly on this job. All of the gear and services are imagined to serve the rearing and rising the birds, so it will be significant that each single matter in a poultry farm, even seemingly unrelated ones equivalent to engineering duties be checked and reconsidered by the sensible animal science professionals, farm managers, and veterinarians.

As many companies, poultry farming is a specialised enterprise, typically very difficult, and it wants totally different professionals to work collectively to satisfy the wants and adjust to the requirements, particularly biosecurity and hygiene requirements. It’s essential for all these professionals to work as a group and take a look at the job with their totally different views. Nevertheless, they have to be conversant in the crucial factors of the job. Errors flip into disasters simply and quickly on this job. All of the gear and services are imagined to serve the rearing and rising the birds, so it will be significant that each single matter in a poultry farm, even seemingly unrelated ones equivalent to engineering duties be checked and reconsidered by the sensible animal science professionals, farm managers, and veterinarians.

The gear performs a big position in complying with the rules of biosecurity within the working section. There’s a variety of kit utilized in a poultry farm, from garments and boots to computerized nests and air flow programs. Gear helps do the job accurately, shortly, and simply. With out applicable gear, the job can be more durable, and extra power consuming, so the chance of misperformance can be larger. Nearly all gear used on a poultry web site, relying on the place they’re used, needs to be washable or washer-friendly as a lot as attainable. Some gear equivalent to nests, AI machine, drinkers, feeders, gentle traps, trolleys, and so forth. needs to be washable. Non-washable gear that are made of cloth, wooden, or cardboards, needs to be modified earlier than the brand new cycle. Another gear equivalent to computer systems and digital gadgets can’t be washed, nor might be modified each cycle. Such gear have to be well-sealed to keep away from mud penetration. For cleansing, a high-pressure air pump and a clear tissue or brush can be utilized. After cleansing, they will both be disinfected by a tissue and disinfecting answer or fumigating by formaldehyde or ozone fuel, relying on the kind of the gear and the supplies used.

Utilizing clean and washable supplies for gear is typically exhausting or costly, however maintain that in thoughts that the damages might be way more costly. Many of the pathogens are very delicate to environmental circumstances and might be simply neutralized on a clear floor, however within the presence of natural residues, their resistance can be considerably larger. Furthermore, the effectivity of disinfectants considerably decreases within the presence of natural residues. To have an thought, H5N1 virus can reside below two weeks at 4 °C outdoors the host’s physique at finest, if protected against sunshine and excessive %RH; however the virus was discovered to outlive as much as eight weeks in dry and moist feces at 4 °C.

Utilizing clean and washable supplies for gear is typically exhausting or costly, however maintain that in thoughts that the damages might be way more costly. Many of the pathogens are very delicate to environmental circumstances and might be simply neutralized on a clear floor, however within the presence of natural residues, their resistance can be considerably larger. Furthermore, the effectivity of disinfectants considerably decreases within the presence of natural residues. To have an thought, H5N1 virus can reside below two weeks at 4 °C outdoors the host’s physique at finest, if protected against sunshine and excessive %RH; however the virus was discovered to outlive as much as eight weeks in dry and moist feces at 4 °C.

Aside from the supplies utilized in gear, the design and manufacturing of the gear are vital as any folds or seams could be a hazard in biosecurity of a poultry web site. Such areas can’t be simply cleaned and take numerous time and power to cope with. Normally, the cleansing group doesn’t put sufficient efforts on these components and in an optimistic situation, the accountable supervisor would request repetition of the cleansing course of. Which means losing numerous time, power, and cash. Despite all that, they will nonetheless be potential hazards.

Certainly, biosecurity might be revered when you actually consider in it; if you concentrate on any particulars of the job, preserving biosecurity rules in your thoughts. It isn’t a play or a present to persuade individuals, it’s a necessity for our job, black or white, there can be no grey when the time comes. Alternatively, as mentioned, ranging from the bottom upon biosecurity rules will scale back the excessive prices of biosecurity procedures. The much less detergents and disinfectants are used, the much less environmental injury is induced, the more cash is saved, and the more cash is gained! Work sensible!