Testing followers on the Bioenvironmental and Structural Techniques Laboratory

In case you are concerned in shopping for or promoting agricultural followers, chances are high you’re aware of BESS Labs. For 34 years, BESS Labs, also called Bioenvironmental and Structural Techniques Laboratory, has been the go-to supply of unbiased fan information for each producers and producers. I not too long ago bought to affix one in every of Hog Slat’s engineering groups for a testing session on the College of Illinois campus.

On the day of our scheduled session, we arrived at BESS Labs on a brilliant however freezing chilly day. Because the engineers ready the primary take a look at fan, I requested lab supervisor Steve Ford in regards to the lab’s origins.

Steve mentioned, “Within the late Nineteen Eighties, a bunch of Wisconsin electrical coops wished to develop a rebate program to encourage the usage of energy-efficient followers. Nonetheless, they found that the cfm/watts information required to create the rebate program was unavailable. Subsequently, the coop personnel contacted the college’s engineering division to carry out the required exams. For the preliminary testing in 1990, the coop bought 40 followers from a number of distributors and shipped them to Champaign.”

Steve defined that BESS Labs has examined as many as 900 followers in a 12 months, however on common, they take a look at between 500 and 600 followers yearly. Followers come from producers worldwide, together with followers not designated on the market within the US. The testing finished by BESS Labs gives international producers with confirmed information accepted all through the world.

So, what’s a wind tunnel?

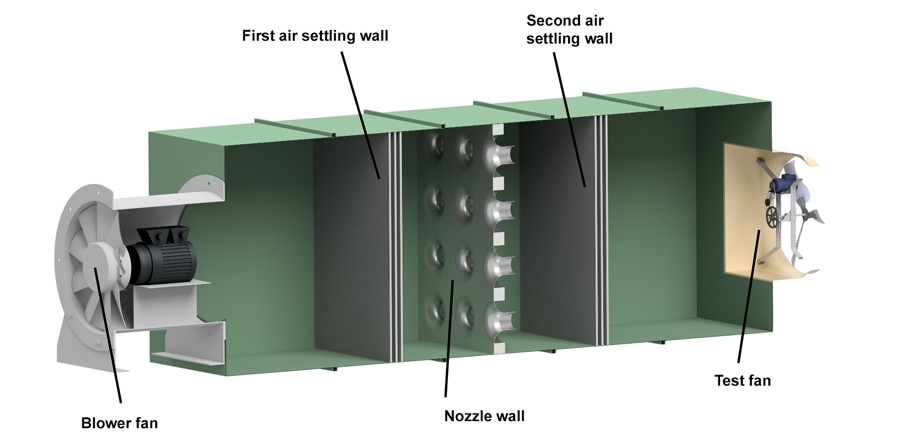

The BESS Lab unit is a 9′ x 9′ x 26′ lengthy wood chamber. To start the take a look at, the group fixed the take a look at fan at one finish of the chamber and warmed up the motor for quarter-hour.

Then, a 50 HP variable pace blower fan on the different finish pushed air via a honeycombed mesh wall referred to as an air settling display screen to even out the movement.

Subsequent, the air handed via a wall of exactly calibrated nozzles with a selected cross-sectional space. Sensors on both sides of the nozzle wall recorded the strain drop as air handed via the nozzles to find out the quantity of cfm being moved. The air then handed via a second air settling wall earlier than reaching the take a look at fan. Steve diversified the pace of the blower fan to check airflow at typical destructive pressures resembling .05, .10, .15, and so on. Further sensors additionally recorded energy consumption at every stage.

Our session included verifying air supply and effectivity for 36, 54, and 57-inch followers with totally different prop, motor, and pulley combos. The engineers have been significantly within the outcomes of the OMNI motor drive powering a brand new fan sequence scheduled for launch later this 12 months. The take a look at confirmed the anticipated effectivity and exact pace regulation, together with appreciable enhancements in motor safety.

The couple of days spent at BESS Labs proved to be an insightful expertise within the fan testing course of. Undoubtedly, their unbiased platform over the previous many years has pushed the effectivity enhancements seen within the followers utilized by the livestock and poultry industries.