Study extra about feed and vitamin

Editor’s observe: This text is an excerpt from the Cobb Breeder Administration Information and extra articles will observe. The Information was designed to focus on essential elements which might be more than likely to affect flock efficiency. To learn or obtain the entire Information or to view Cobb’s different administration guides, click on right here.

The primary goal of any broiler breeder operation is to provide fertile settable eggs that, when hatched, will provide the mandatory amount of excellent high quality chicks to satisfy the broiler manufacturing calls for. Administration within the first week submit hatch is a significant contributor to any profitable breeder administration program. Key indicators of flock efficiency are the typical body weight, and flock uniformity in addition to mortality at day 7. Attaining good flock uniformity in the course of the manufacturing part could be attributed to the technical work performed in the course of the rearing part. Nonetheless, it isn’t sufficient to depend on data and technical abilities. Plan, arrange, carry out and monitor key efficiency indicators together with rearing and manufacturing body weight curves and feed consumption. You will need to monitor these key indicators and reply early to points.

The usual body weight curve throughout rearing is a primary instance of one in every of these indicators. Failure to keep up a rearing flock on the usual body weight curve can have significantly detrimental penalties on flock productiveness. Managing and monitoring feed consumption requires consideration to feed formulation, ingredient selection and feed kind to make sure predictability as regards to consumption and body weight response in comparison with the usual grams/hen/week. Breeder body weight administration can also be dependent upon the standard of weighing and feeding tools.

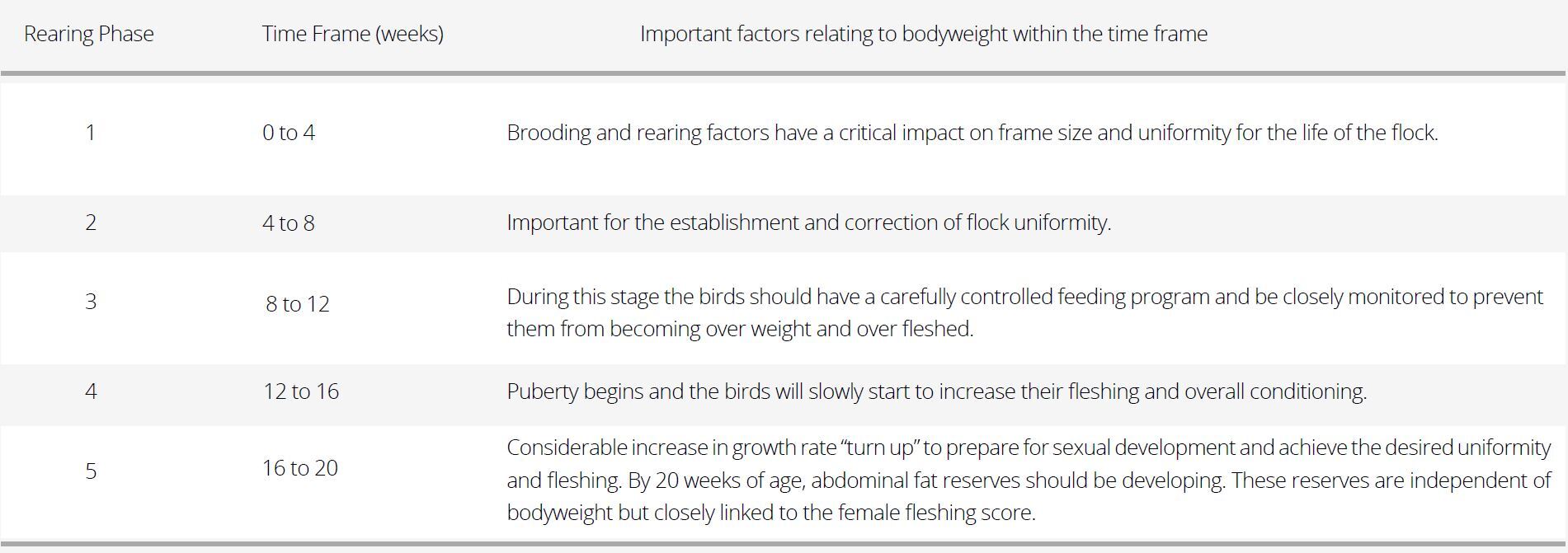

Males must be raised individually from the females as much as 20 to 21 weeks of age for finest outcomes. Rearing could be damaged down into 5-time frames every consisting of 4 weeks and every time-frame having necessary elements concerned within the body weight curve.

Feed consumption

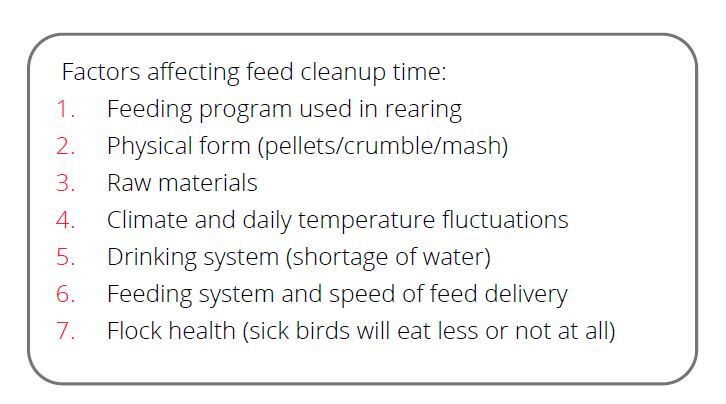

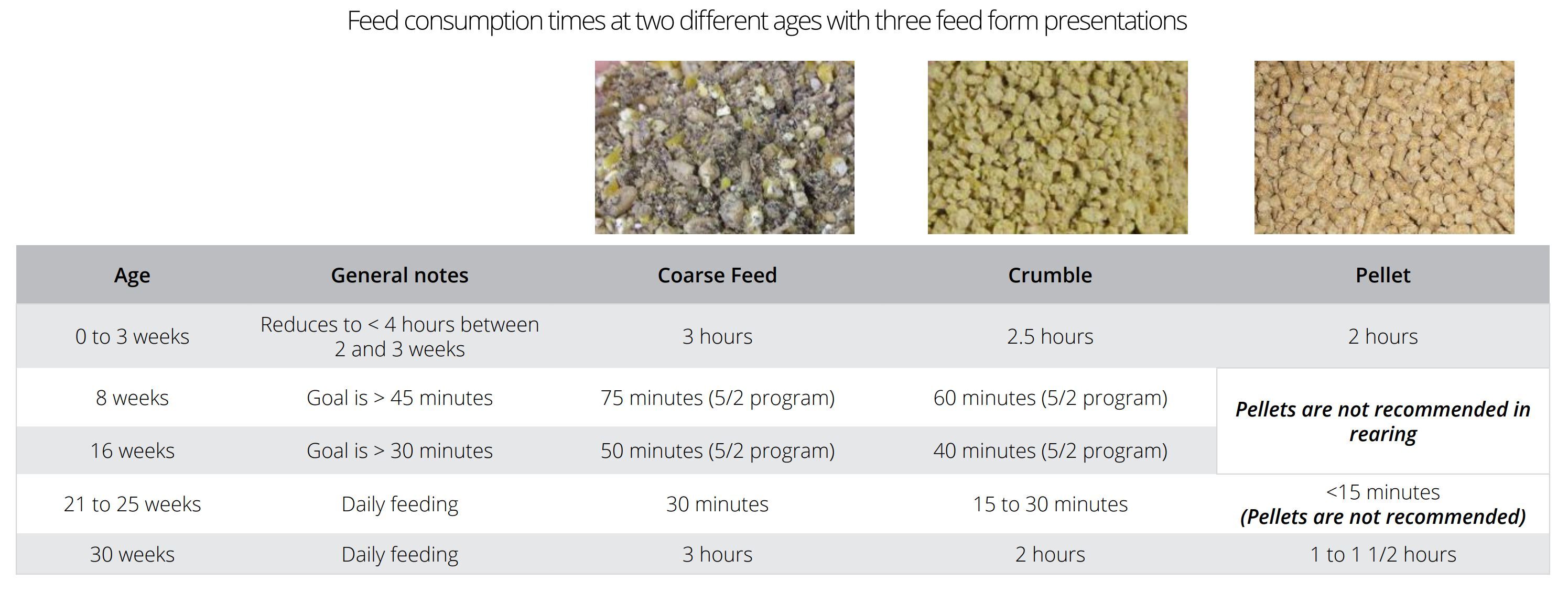

Feed consumption time, or feed cleanup time, is a key consideration in each the rearing and manufacturing durations. Cleanup occasions will differ over the rearing interval and depend upon a number of necessary elements together with feed quantities, genetic line, the kind of feeding program, the feed kind offered and light-weight depth being utilized in the home.

Within the rearing interval, pullets will begin quickly cleansing up the feed in the course of the managed development part. Enable a feed cleanup time of about 40 to 60 minutes from 10 weeks of age till photograph stimulation. This gives sufficient time for equal entry to feed. If cleanup time is lower than half-hour, improve feed quantity and lengthen cleanup time by making use of an different feeding program corresponding to 5/2 or 4/3. Within the manufacturing interval, hen cleanup time is likely one of the indicators used to find out the primary feed lower after peak manufacturing.

Key dictators of cleanup time are feed texture and dimension. In rearing and manufacturing, we advocate a crumble to lengthen feed consumption time. Some producers could use mash coarse feed, which will increase consumption time in comparison with a crumble. We discourage utilizing pelleted feed in rearing or manufacturing since it may be consumed shortly and there could not be sufficient quantity to ensure equal distribution.

Constant timing of feed supply is necessary for the flock and welfare and is as necessary as ‘when the birds eat’ (i.e. time of the day) and ‘how usually birds eat’ (i.e. feeding program). Birds will be taught when to anticipate meals and can modify accordingly. Irregular feeding schedules or a disruption within the regular feed routine could be very worrying for the flock. Constant feeding occasions are essential for hen well being and good welfare outcomes. When transitioning from one feeding program to a different, observe flock conduct, cleanup time, and exercise degree and try to maintain the time level of feeding the identical.

The significance of vitamin

The right feed formulation and dietary content material is required in order that breeders categorical their genetic potential and produce fertile hatching eggs. Moreover, prime quality substances should be used to make sure the hatching eggs are freed from contaminants and comprise all of the vitamins wanted for hatching wholesome broiler chicks.

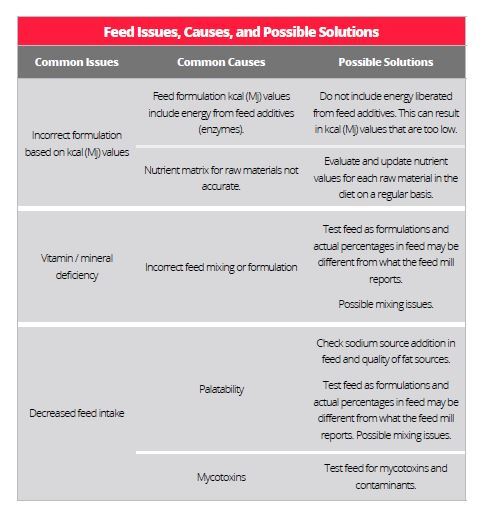

The right feed specs are a vital consider rearing and manufacturing for prime performing flocks. Diet performs a key position in getting ready pullets for manufacturing. Good rearing administration with excessive uniformity and bodyweights on normal won’t assure good manufacturing if the pullets are usually not conditioned correctly as a result of inferior feed specs. Constant outcomes will all the time be a problem if the feed is lower than specs. The feed specs have to be built-in into the administration strategies to know why and the way the pullets develop, develop, feather and put together for photograph stimulation. At all times buy good high quality feed substances and formulate diets primarily based on the Cobb specs obtainable in our dietary supplements (http://Cobbgenetics.com/reso…).

An ordinary feeding profile must be adopted throughout rearing to maintain bodyweights on the usual curve. Any small deviations from normal in body weight could be adjusted with small 1 to 2 g feed increments. As soon as established, use the feeding program as a normal information throughout rearing. Body weight can fluctuate inside +/-2 % of the usual. For constant efficiency, stop adjustments in feed formulation and monitor every feed supply. Report any issues instantly. Feed samples must be saved on the farm for testing if essential.

Key factors for feed formulation and vitamin

- Acquire samples of feed and write detailed notes (date combined, date acquired, feed sort (starter, breeder 1, and many others.)) on the sampling container.

- Conduct common audits that embrace sampling and testing of ingredient suppliers and the feed mill.

- Rigorously select feed enzymes and match them with native uncooked supplies as enzymes affect substrates obtainable for microbial fermentation within the hen.

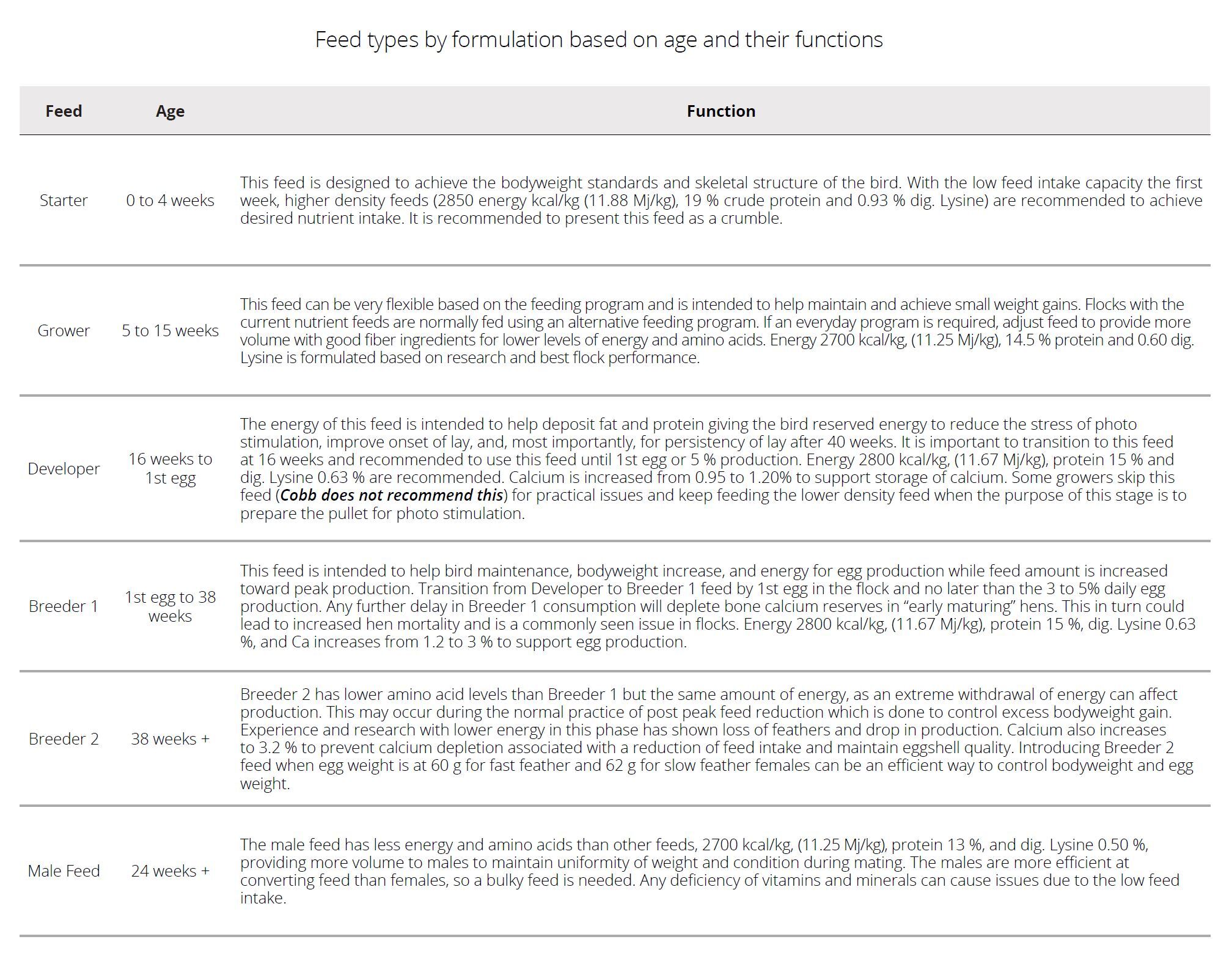

- Use the Cobb feed specs and make sure you change feeds on the right flock age (see subsequent web page for descriptions of every feed formulation).