Chemical dyes wield a major however typically ignored affect on India’s setting. Within the bustling textile business, the place colors flourish, the widespread use of chemical dyes presents a multifaceted menace to the setting.

These dyes, laden with heavy metals and poisonous compounds, discover their approach into water our bodies, soil, and air, polluting essential pure sources. They not solely pollute nature but additionally have an effect on the meals chain in water our bodies.

As per a analysis paper by Science Direct, “The textile dyes additionally act as poisonous, mutagenic and carcinogenic brokers, persist as environmental pollution and cross complete meals chains offering biomagnification, such that organisms at increased trophic ranges present increased ranges of contamination in comparison with their prey.”

Alternate options equivalent to utilizing flowers to make colors and textile dyes have been gaining recognition, however they arrive with a set of challenges together with availability, possibilities of fading and price.

“There may be additionally a difficulty of color consistency. The textile business wants the color to be of the identical consistency on each fabric which turns into troublesome with flower-derived colors,” says Vaishali Kulkarni of KBCols Sciences.

KBCols is a science firm that makes pure dyes. Co-founded by Vaishali Kulkarni and her husband Arjun Singh, the corporate has discovered a approach of constructing pure dyes from waste by utilizing microbes!

How does the science behind this work? The founders clarify the intricacies in an interview with The Higher India.

‘This was future’

Born and raised in Mumbai, Maharashtra, Vaishali informs she by no means deliberate that she would grow to be an entrepreneur. “I’m a science individual however the flip of occasions led me into the color business,” she says.

After finishing her postgraduate research, she determined to go for a PhD from a school in Mumbai.

“Throughout my PhD research, initiatives typically got here to our school in regards to the remedy of colored water within the textile division. Researchers had been tasked with addressing this difficulty by using numerous unit operations to purify the water. It grew to become evident that prevention was higher than remedy,” she ponders.

This gave me an concept about how she may make pure dyes as an alternative of making an attempt to purify the contaminated water.

It was throughout this time that she met Arjun, who had the same concept.

“We aimed to deal with the basis trigger moderately than cope with the results. This led us to the realisation that as an alternative of managing the discharge of dangerous colors into the water after their use in textiles and different industries, it could be extra prudent to develop safer options. This concept sparked our curiosity, and we started engaged on it diligently,” she informs.

As soon as the PhD was full, she determined to try to safe a grant from the federal government.

“We utilized for a grant, and it was awarded to KBCols to conduct proof-of-concept (POC) research. As per the grant necessities, we needed to choose an incubator centre if we didn’t have entry to a lab or any particular subjects in thoughts,” she recollects.

“The closest one to Mumbai was in Pune, the place the Enterprise Heart offered this facility. Consequently, we had been incubated there, and our journey started in earnest in 2018,” she provides.

The corporate was based by the duo the identical yr, they usually have been working ever since to make natural colors from waste.

“Everyone knows that colors are ubiquitous, present in practically each business, together with textiles, meals, and cosmetics. We regularly affiliate particular colors with sure merchandise, just like the expectation that apples ought to be pink. Consequently, colors performs a major function in our day-to-day actions,” says Vaishali.

With about 80 % of the industries on this planet utilizing chemical dyes, they’re affecting our petroleum sources too.

“These dyes are primarily derived from petroleum sources, that are finite. Subsequently, it’s inevitable that someday, these petroleum sources will grow to be exhausted. An efficient different was the necessity of the hour,” she says.

In right now’s market, choices within the type of vegetable and flower colors can be found, however they lack sustainability.

“They require huge quantities of land for cultivation. For example, rising particular crops or flowers necessitates intensive land sources and is commonly topic to seasonal differences, taking months to mature,” she says.

Utilizing microbes to make colors

One of many major challenges confronted by the business with these flower and vegetable colors is their lack of reproducibility. Their colors differ, making it troublesome to realize consistency. This inconsistency prevents their widespread adoption on an industrial scale.

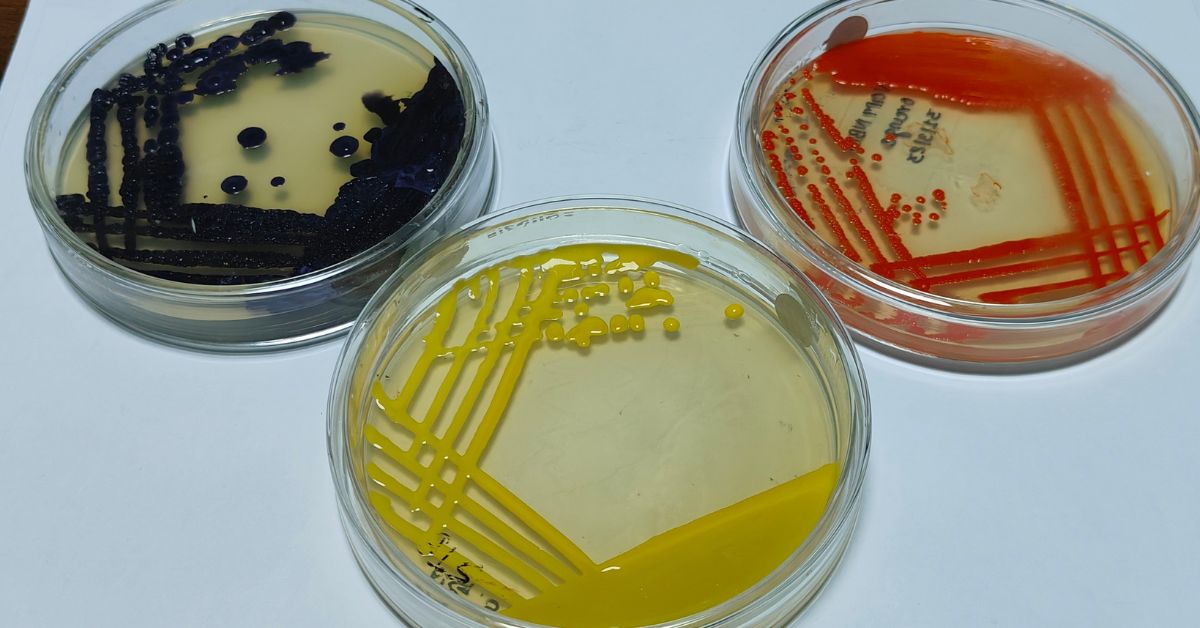

“To deal with this difficulty, the duo determined to make use of micro-organisms. Our colors are pure bio-colours, providing a dependable and sustainable answer to the challenges posed by conventional vegetable and flower colors,” she states.

The uncooked supplies to make these colors are derived from waste.

“Microorganisms possess inherent properties that allow them to supply colors, as reported within the literature. Nonetheless, regardless of this data, nobody in India has ventured into industrial or industrial manufacturing utilizing this technique,” she says.

Recognising this untapped potential, the duo determined to discover this space and provide pure color choices.

“Our method includes utilising a mix of plant or vegetable colors. These colors might be cultivated inside a vertical reactor, permitting for environment friendly manufacturing inside a batch time of 16 to 24 hours,” she says.

She continues, “Remarkably, this course of doesn’t depend on petroleum sources or excessive temperatures for cultivation. As a substitute, we utilise agricultural waste, together with sugars and salts, to domesticate the microorganisms throughout the reactor.”

Speaking in regards to the analysis and improvement course of, she talks in regards to the limitations that include utilizing microbes.

“Microorganisms have a tendency to supply color when subjected to emphasize. Subsequently, we should acquire samples from numerous environments the place microorganisms are naturally uncovered to stressors. To isolate the pigmented microorganisms from the multitude of micro organism and microorganisms includes accumulating soil samples and screening water and air samples from various places. Remarkably, even a tiny quantity of soil, only one milligram, can yield hundreds of microbes,” she says.

She provides, “Whereas this analysis and improvement section is time-consuming, as soon as we’ve efficiently remoted a microbe with a desired color, it turns into a priceless proprietary asset of the corporate.”

How did it translate out there?

Isolating microbes being a time-consuming course of is what has delayed the couple from launching their merchandise out there.

“We beforehand collaborated with a designer primarily based in Pune, to launch a small assortment. This assortment was showcased on the Lakme Vogue Week 2022 in Delhi, the place fashions wore clothes dyed with our colors. Whereas this served as a comfortable launch, our official industrial launch is scheduled for both the tip of this yr or the subsequent,” she informs.

Speaking about how their colors are aggressive with the artificial colors out there, Vaishali explains, “In textiles, the efficiency parameters are primarily based on three facets: color fastness to gentle, washing, and rubbing. Color fastness to gentle refers back to the material’s means to withstand fading when uncovered to daylight. Washing fastness assesses how nicely the color holds up when subjected to harsh detergents. Rubbing fastness measures the color stability of the material underneath friction.”

For every parameter, industrial requirements usually vary from 1 to five, with the next worth indicating higher efficiency.

“Chemical colors typically rating an ideal 5, whereas our pure colors usually obtain a score of three to 4 for gentle fastness and 5 for laundry fastness which is an appropriate business commonplace,” she says.

Sharing her future plans, Vaishali informs that the duo is concentrated on launching the product as quickly as doable.

“At present, we’re additionally within the means of developing our demonstration plant in Pune, with an estimated capability of round 500 kg per thirty days. This enlargement goals to extend our manufacturing capability. Moreover, we plan to diversify into the cosmetics and meals sectors, along with textiles,” she shares.

Need to know extra about their ingenious expertise? Go to their web site to know extra.

(Edited by Padmashree Pande)